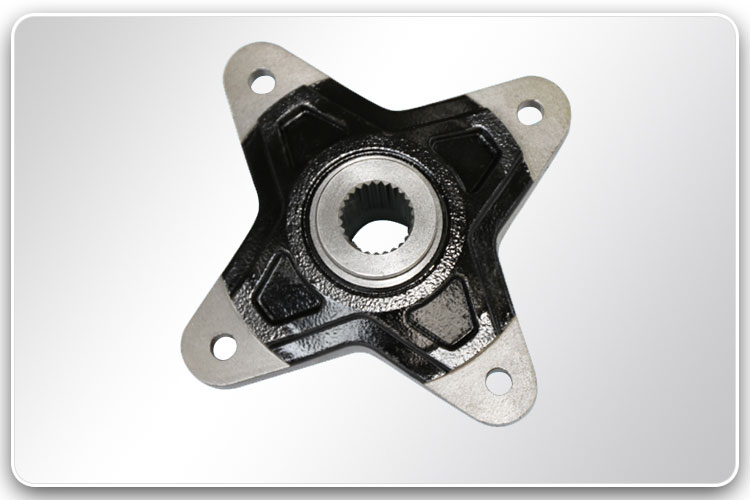

The wheel hub assembly

includes wheel studs that attach the wheels of the vehicle

to the car and is mounted to the steering and suspension system on the front

end and the rear axle on the rear end.

Auwell wheel hub

is mostly made by forging followed by CNC milling, then surface treatment. In

some cases, investment casting is also the process for production. The material for wheel hub mostly is alloy

steel but some of them made by aluminum. As an OEM components supplier, Auwell

develops wheel hub in accordance with clients’ drawings and specifications.

Договорот за производство на Овел е специјализиран за производство на различен вид на зглобови на тркалото и на управувачот, спојници за спојување, како и делови за ракави за шини за автомобилска индустрија.

Прикажаната слика ја демонстрира нашата производна способност. Клиенти кои се заинтересирани за развој на производи со тркала, ве молиме контактирајте не за детали.

Auwell Advantages

-Богато искуство

More than 10 years of

experience in Wheel Hub products development and production, with solid understanding

of the material, technical and quality standards worldwide.

-Fast Turnaround

Општо, ние обезбедуваме понуда во рок од 3 работни дена. Комбинирање на најновите технологии и можности за производство, Овел може да обезбеди брзи прототипови за само 2 недели за едноставни проекти.

-Давател на сеопфатно решение

Овел обезбедува сеопфатни услуги за проектите на Тркала за центар, почнувајќи од дизајнирање, протолотирање, развој на алати / опрема, земање примероци, масовно производство и до логистичка поддршка и поддршка по продажбата.

-Цврсти политики за КК

The most rigorous quality

policy starts from material control, and is followed through to final

pre-shipment inspection. For quality control of Wheel hub parts, we provide set

of test reports including chemical components, mechanical property, X-ray test,

metallographic analysis report etc. For dimension inspection, we offer 3D

scanning report, also CMM is available for inspection. We structure our

processes, creating Flow Charts and Control Plans before production, making

sure all QC processes are in accordance with TS16949 requirements and drawing

specifications.

-Флексибилен рок на плаќање

Tooling payments need to

be pre-paid. For mass production, we offer flexible payment terms, reasonable

credit terms will be given, the client only pays when they are happy with the

product they received. For long-term projects, we offer call-off inventory

services for fast delivery requirements.

For details about

our steering knuckles, spline connectors and Spline Sleeve Parts, kindly please

visit following links:

Steering Knuckles

Врвни конектор

Spline Sleeve Parts

The following catalogues of wheel hub parts are the ones that Auwell has

produced and supplied to our distinguished worldwide clients. Please click the

relevant pictures for details. Please be advised, most of the products are for

demonstration purposes only.

English

English  Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी  Srpski језик

Srpski језик